source:Han sai

source:Han sai date:2022-06-20

date:2022-06-20Gene therapy as an epoch-making technology, for human a variety of refractory diseases, especially genetic defects have brought the hope of "cure", after more than 30 years of research accumulation and innovation is now finally entered the take-off stage, in the field of more than a dozen diseases hundreds of indications have shown a huge application prospect. Recently, the Exegenesis Bio (Compound Biotechnology) gene therapy drug project contracted by The Times Group was officially put into operation, injecting new impetus into the development of China's gene therapy industry and supplementing the scarce targets in the domestic market.

Exegenesis Bio (Hangzhou Fuyin Biotechnology Co., LTD.) is a biopharmaceutical enterprise in the industrialization research and development and clinical application of gene therapy drugs. Exegenesis Bio is positioned to develop Best in class and First in class gene therapy drugs for different markets, focusing on orphan drugs and major diseases, and has a unique gene therapy platform.

Exegenesis Bio Hangzhou Building exterior location

Group the compound biotechnology gene therapy drug project phase ii project-PLA raw material project (hereinafter referred to as "compound project"), services include: r & d laboratory and GMP production plant process equipment pipeline engineering, strong and weak electrical engineering, air conditioning system engineering, utilities engineering materials equipment procurement, installation, commissioning, and production plant, air conditioning system, GMP warehouse verification, can meet the requirements of FDA and EMA cGMP.

Clean area corridor

BIM first to create a scientific layout

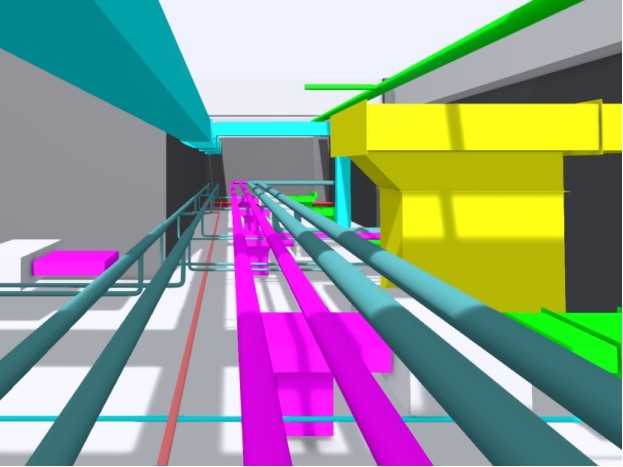

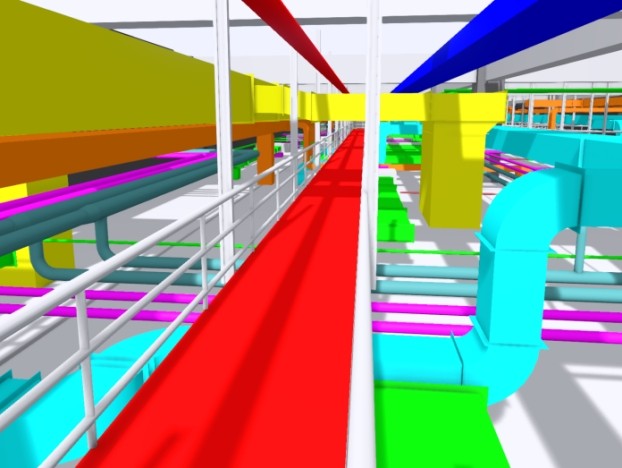

The construction area of the project is 6000 square meters, of which the purification plant area is 2500 square meters, the main structure is mainly clean engineering, and there is a small interlayer space and thus dense pipelines. In order to solve this problem, the BIM Center team of The All Times Group helps the owner to clearly distinguish the air supply and exhaust systems in the later stage to improve the maintenance efficiency. Through BIM technology, the air supply and exhaust pipes are set at two different heights, which greatly improves the space management of the air supply and exhaust system.

BIM rendering of the duct duct

In the arrangement of other pipeline systems, the injection water, frozen water and other pipelines are combined into a unified system pipe corridor, so as to reduce the fan coil in the sandwich from 6 to 2 to 3 levels, making the overall pipeline layout simple and beautiful. At the same time, in order to facilitate the later inspection, the designers make full use of the space, in the already narrow mezzanine space is also specially arranged for the maintenance personnel to travel. All the details reflect the perfect Group in the project with comprehensive consideration and detailed design of high standards, strict requirements to complete the expected goals of customers.

BIM renderings of the pipe gallery and horse path of the project

Optimize the design to create high-quality projects

Optimization design is the characteristic of the modern group project management. Before the start of the project, the project team will organize the process, design, construction, cost engineers and other relevant personnel to carefully analyze and understand the drawings, find problems, optimize the process, and ensure that each project is turned into a high-quality project. In the optimization design of the project, the project technicians give full play to their technical advantages, adjust the room layout, opening direction and room size, better meet the pressure difference requirements, facilitate logistics and transportation, and meet the escape principle; help the owner to perfect the URS writing of clean equipment, and improve the function; combine color plate layout and HVAC design to determine the outlet point in advance, and improve the beauty.

Compound factor project equipment room and clean area

Civil and military " both deliver a perfect answer

In the biopharmaceutical industry, the verification work is a very important link. As a link of the "liberal arts" in the whole process of the project life cycle, but the text is not soft, the verification activity is a sharp weapon to effectively control all the key elements. Therefore, it requires a strong degree of professionalism and enough engineering construction experience, and also needs enough meticulous and patient implementation to ensure the "controllable process" of the project.

The project is a four-storey single building, covering GMP warehouse, production workshop, PD research and development, QC laboratory, etc., each system has many and miscellaneous systems, and the verification workload is large. As the main responsible party, the Group verification team gives full play to its own advantages in verification experience, and actively coordinates and coordinates the joint development of all parties with the cooperation of the owner's engineering department. Finally, the SAT / IOQ work was completed in advance, so that it has successfully entered the PQ and the subsequent trial production stage.

Duine project validation file

Times group biomedical engineering general contracting team has international vision and advanced concept, is the science and technology strength to build boutique project "golden signboard", maintain strategic cooperation with international famous consulting company CBC onsultancy AG, biomedical enterprises to provide professional consulting, design, procurement, construction and GMP compliance services of one-stop engineering general contracting solutions. At present, The Group has provided high-quality services for many leading biopharmaceutical enterprises such as BaekShenzhou, Kangsino, Junshi Biology, Heyuan Zhizao, Nuocheng Jianhua and so on, contributing to the development and transformation of the pharmaceutical industry.

BOOK

BOOK 中文

中文

Tender Hall

Tender Hall  Resource Center

Resource Center

RETURN

RETURN